Other products

Forge-welded gratings - SP

»

Basic terminology

»

Serration

»

Stair treads

»

Fixing material

»

Load table of SP gratings

»

Surface treatment

Pressure-locked gratings - P

Perforated metal planks - B

GRP gratings

Stair treads

Spiral staircases

Other products

Do you have a question about products?Write to usOr call us

+420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.czAsk a question

Forge-welded gratings - SP

Lichtgitter started the manufacturing of forge-welded gratings in 1966. The manufacturing technology has undergone a long-term development and the main emphasis has been placed particularly on quality, productivity, market satisfaction with a sufficiently wide type range and perfect services. This policy has led Lichtgitter to the absolute top in the field of the manufacturing of floor gratings.

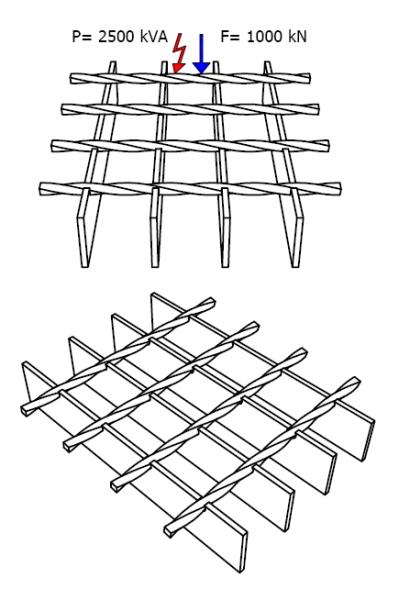

Construction principle

The bearing structure of the grating is made up of steel strips the mutual position and stability of which is secured with spacing bars. Spacing bars are made of a drawn twisted wire. Apart from securing the position and stability of bearing bars, spacing bars serve for a partial distribution of loading on the bearing bars outside the loaded surface. This fact is applied also in the static analysis for the grating dimensioning.

Manufacturing technology

Spacing bars are welded into gross bearing bars by bringing a current of up to 2500 kVA and by concurrently exerting a pressure of up to 1000 kN. Owing to the quality welding of contact points, the formed "net" structure has both a high strength and the ability to distribute loading favourably. In the cross direction, gratings are edged using a method at which the edge with the double offset along the entire length is always welded with each bearing bar. Edging is done on an automatic welding machine which guarantees the top quality of welds. In addition, corners are secured with spot welds. Only for atypical dimensions and shape gratings are edges welded manually.

Manufacturing programme - Manufacture according to DIN 24 537-1

Material: S235 JR (acc. to EN 10025-2: 2004)

Standard width (we recommend using in the maximum possible extent)

The manufacturing technology of forge-welded gratings determines the maximum width of grating 1000 mm. This is the width of an endlessly long bar coming out of the manufacturing line, which is further divided to the required dimensions (bearing lengths). The value 1000 mm is the rated dimension of the grating. By shrinkage of material after welding (approx. 2-3 mm), the actual dimension of the grating 997 to 998 mm is made.

Manufacture width

Width other than 1000 mm, the whole multiple of the axis pitch of bearing bars, i.e. for example: 34.33 mm + 1 bearing bar thickness (dimension "for an entire mesh") - see the table. Does not require any additional edging in the bearing direction!

Table of the manufacture widths of SP gratings

| Bearing bar th.=2mm |

38, 72, 107, 141, 175, 210, 244, 278, 313, 347, 381, 416, 450, 484, 519, 553, 587, 622, 656, 690, 725, 759, 793, 828, 862, 896, 931, 965, 1000 (standard width) |

| Bearing bar th.=3mm |

39, 73, 108, 142, 176, 211, 245, 279, 314, 348, 382, 417, 451, 485, 520, 554, 588, 623, 657, 691, 726, 760, 794, 829, 863, 897, 932, 966, 1000 (standard width) |

| Bearing bar th.=5mm |

41, 75, 109, 143, 178, 213, 247, 281, 316, 350, 384, 419, 453, 487, 522, 556, 590, 625, 659, 693, 728, 762, 796, 831, 865, 899, 934, 968, 1001 (standard width) |

These are rated dimensions that are subject to manufacturing tolerances acc. to RAL GZ 638. The difference between the rated and actual dimensions is a mounting clearance; if working with rated dimensions, it is not necessary to add any additional clearance.

Width not corresponding to the manufacture dimension; it is necessary to perform additional edging in the longitudinal direction!

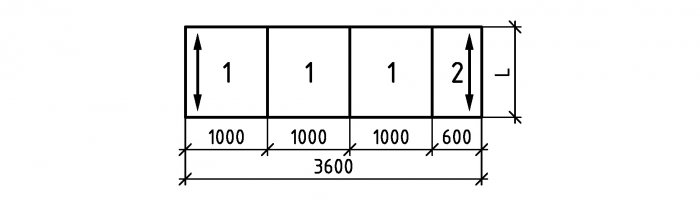

Example of laying gratings:

Dimension of semi-finished products (mats)

6100x1000 mm

Axial pitches of bearing bars and spacing bars - dimension of mesh

In the standard type of a forge-welded grating (acc. to DIN 24537-1), the axial pitch of bearing bars is 34.33 mm and that of spacing bars 38.1 or 50.8 mm. These types comply with the requirement of the CSN EN ISO 14122 standard for the ball not falling through D=35mm. After deducting the thickness of both elements, the clearance of meshes is approx. 31 x 32 or 31 x 45 mm. Upon the customer request, gratings with the following mesh dimensions can be supplied:

Mesh dimensions

|

| |

Bearing bar pitch |

Spacing bar pitch |

| Standard mesh |

34.33

|

38.10 |

Meshes complying the standard for

falling-through of a ball 20 mm in diameter |

15.56

21.64

34.33

|

76.20

76.20

24.00 |

| Other common mesh dimensions |

34.33

34.33

34.33

41.46

|

50.80

76.20

101.60

101.60 |

Different mesh dimensions depending on demand.

Standard range

Bearing bar

| height |

thickness |

| |

2 mm |

3 mm |

4 mm |

5 mm |

| 20 |

- |

o |

- |

- |

| 25 |

o |

o |

- |

o |

| 30 |

o |

o |

- |

o |

| 40 |

o |

o |

o |

o |

o …standard production of Lichtgitter CZ

- …these and other heights and thickness (up to the dimension of 80x5 mm) on demand.

Type designation of gratings

Forge welded grating SP

Cross bar 30 x 3 mm 330

Bearing bar spacing 34,33 mm 34

Cross bar spacing 38,1 mm 38

Binding bar 30 x 3 mm 3

SP 330-34/38-3

Anti-slip type

For the normal conditions of using floor gratings, the anti-slip properties of common forge-welded SP gratings or pressure-locked P gratings are sufficient. For environments with an occurrence of oils, ice or other impurities increasing the slip hazard and when using gratings on inclined foot bridges it is necessary to use gratings with anti-slip design. The anti-slip design consists in a special shape finish of bearing or spacing bars. Lichtgitter offers several types of the anti-slip design of gratings for various applications.

Anti-slip type designation

The anti-slip types of forge-welded gratings are designated with the upper-case letter X before the designation of individual types.

Designation (for example): XSP 330-34/38-3, No. 1

.

+420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.cz

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.  +420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.cz