Fixing material

- We recommend our specially developed Lichtgitter fixings for all types of perforated metal planks and underside support.

- The clamp upper part with BZ-gratings is an „olive“. For all other types no special upper part is necessary.

- All screws and nuts are either supplied in stainless steel, or like all other fixing parts, supplied centrifugally galvanised.

- By screwing together perforated metal planks (if possible, at every 500 mm centres, see fixing no. 27, 29), stumbling edges are avoided and a greater level of load distribution is achieved.

- Perforated metal planks should be prevented from lifting up and slipping off. Every element having a width greater than 300 mm should be attached from at least four points to the underside support, otherwise two fixings are sufficient.

- All fixings require service and should be regularly inspected regarding their efficiency. The inspection intervals depend on operating conditions.

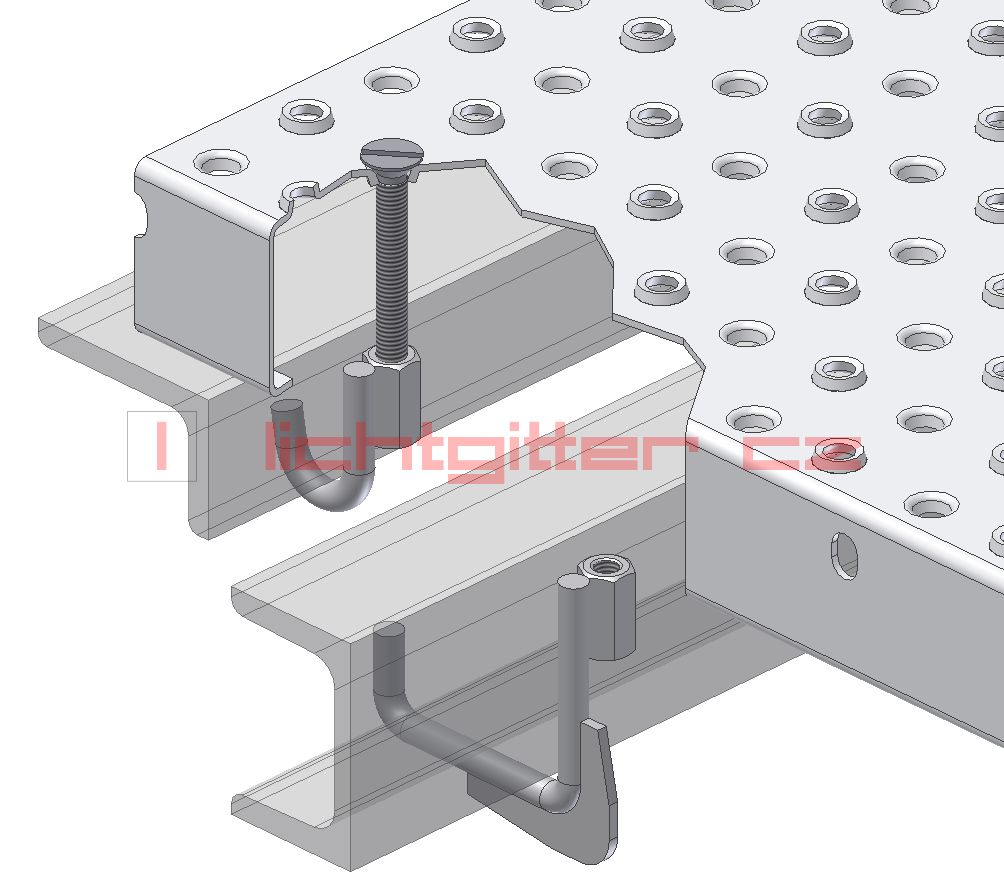

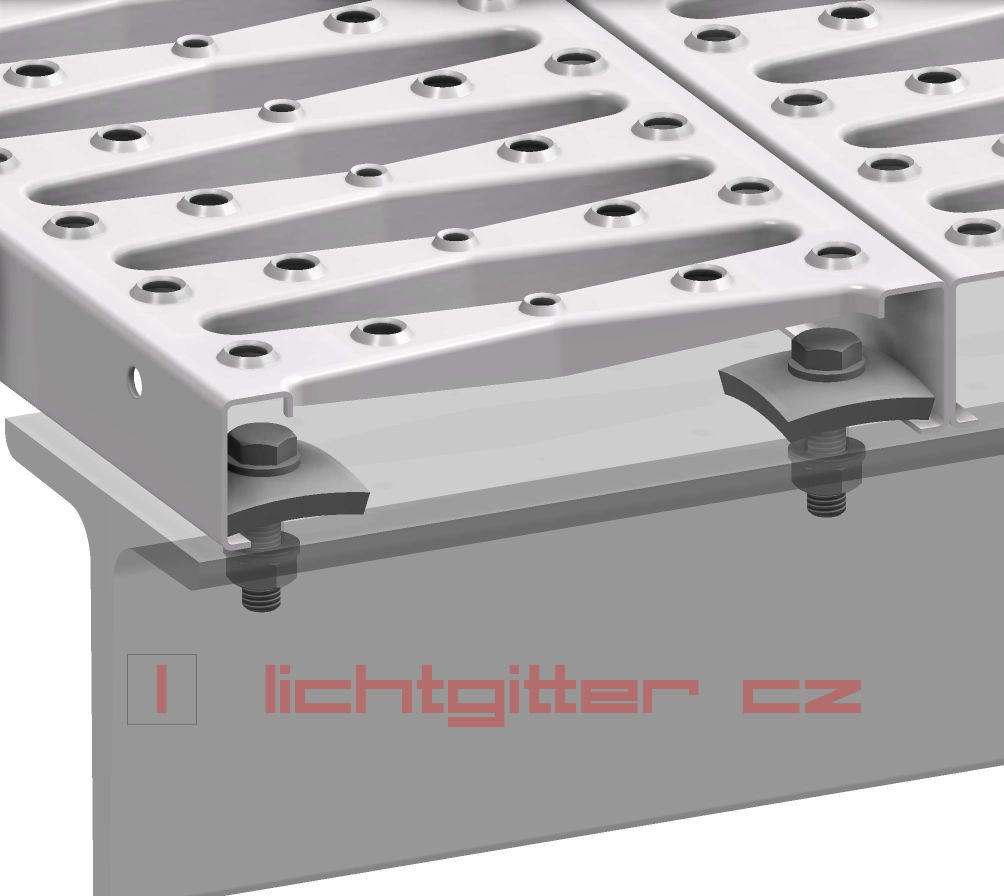

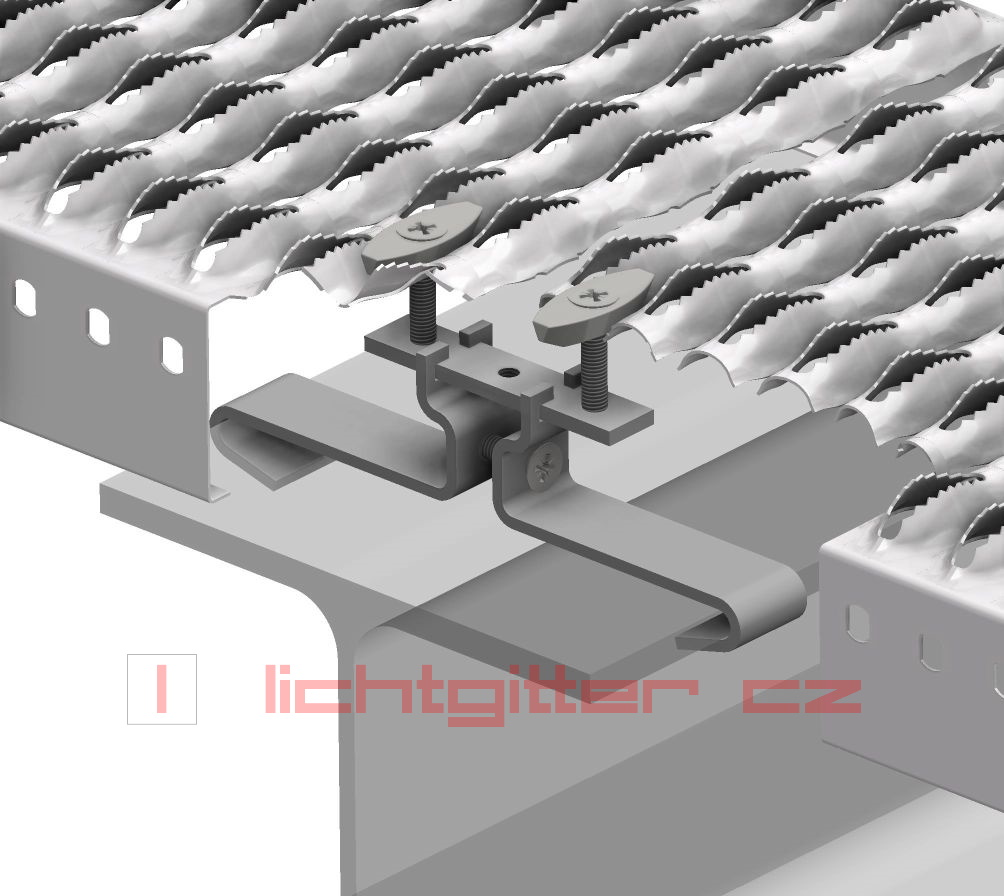

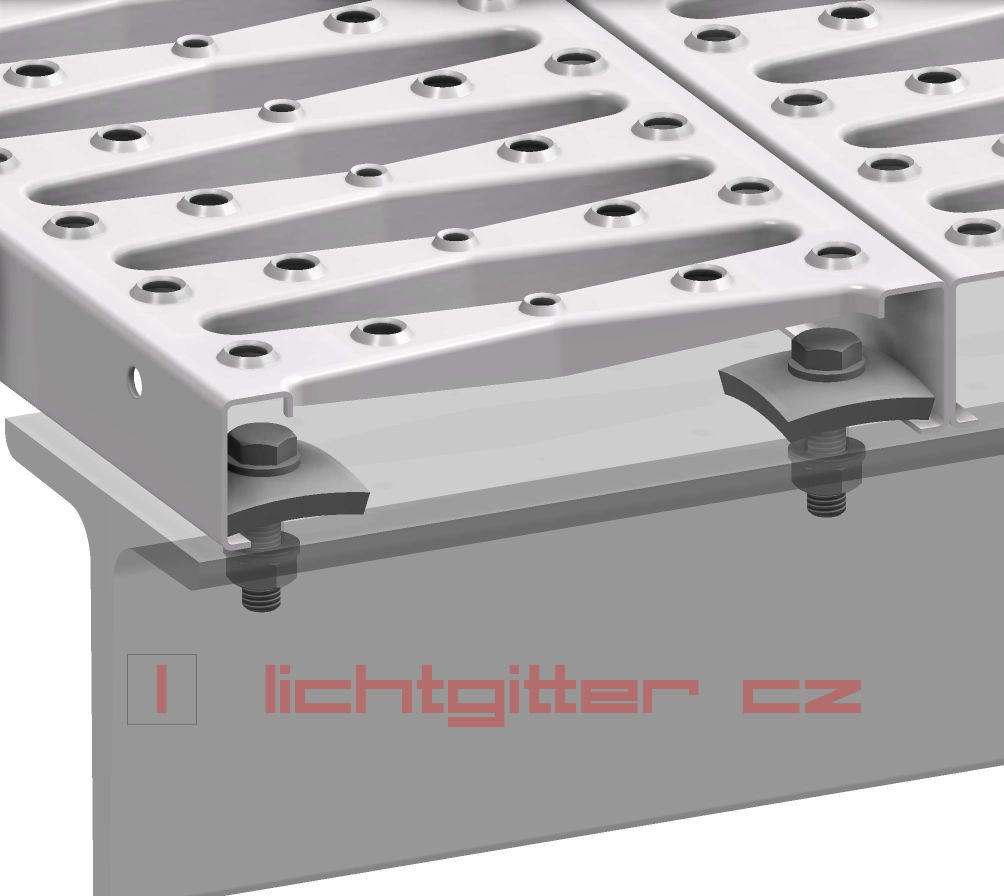

No. 21 Standard fixing

clamp connection, consisting of:

- clamping lower part

- countersunk screw M8 x ... ISO 2009 (DIN 965)

- square nut M8 DIN 557

- and for BZ-gratings additionally with „olive“

This fixing is suitable for the types BR, BP, BP-Ü, BZ and BN-O.

No. 22, 23 Hook screw-fixing

No. 22 for perforated metal planks on vertical support profiles without bottom flange,

consisting of:

- clamping lower part

- flat head screw M 8 ....ISO 2009 (DIN 965)

- and for BZ-gratings additionally with „olive“

profile of underside support must be indicated upon order.

No. 23 as per no. 22, but vertical support profiles with bottom flange.

This fixing is suitable for the types BR, BP, BP-Ü, BZ and BN-O.

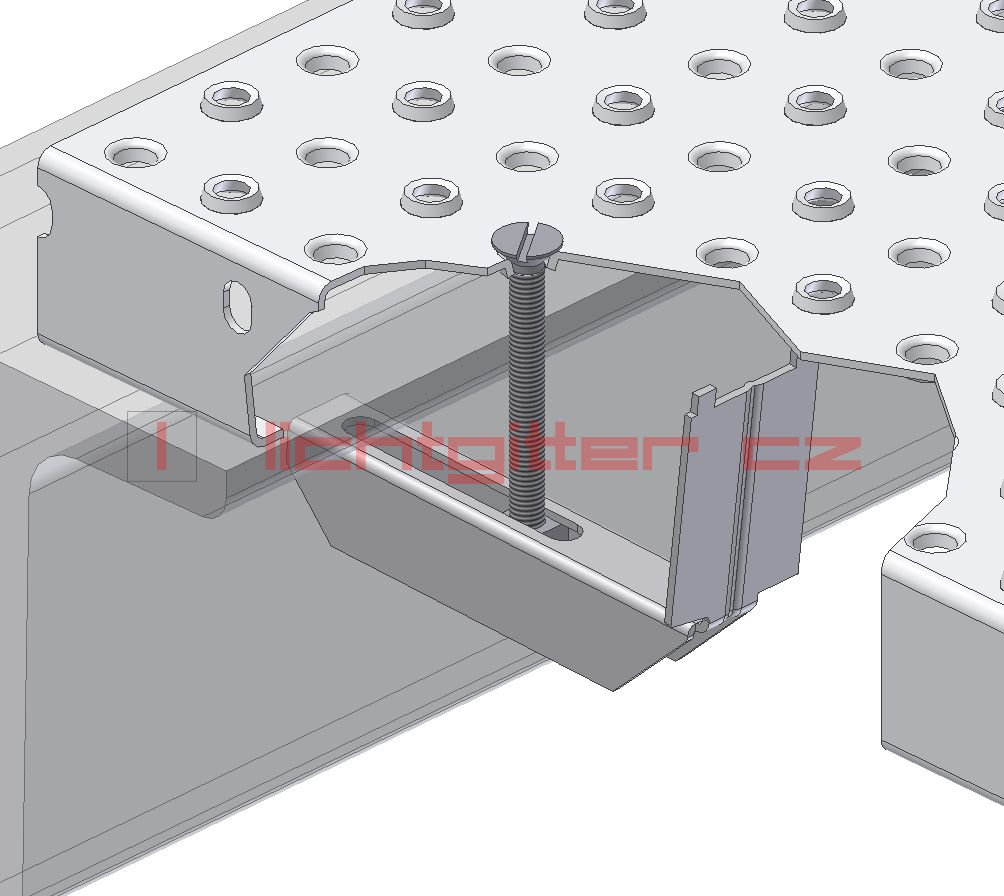

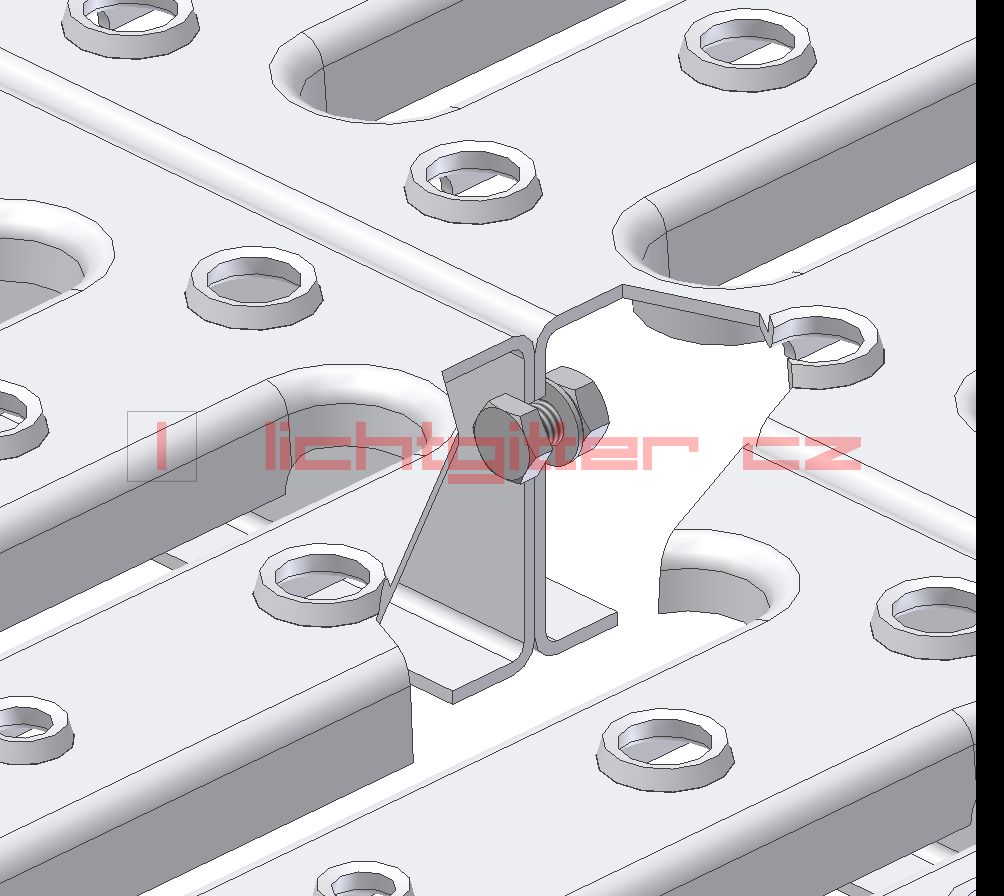

No. 24 Thrust connection

avoids stumbling edges at intersection and enables an attachment to underside support. Consisting of:

- U-Profile

- flat head screw M 8 x ...ISO 2009 (DIN 965)

alternatively: tapping flat-headed screw acc. to ISO 7050 (DIN 7982)

- washer 9 DIN 126

- nut M 8 ISO 7042 (DIN 980), self-locking.

This fixing is suitable for the types BN-O and BN-G. Necessary boring in the perforated

metal plank BN-G has to be done at site.

No. 24 Butt joint - new

serves as a fastening without drilled holes for perforated metal plank, whilst at the same time providing spacing from the substructure. Consisting of:

- 2 clamping brackets

- Threaded bars with 3 countersunks M8 x ...... according to ISO 7050 (DIN 7982)

- 2 olive (see fastening no. 32)

Fastening material suitable for BR, BP, BP-Ü, BZ and BN-O.

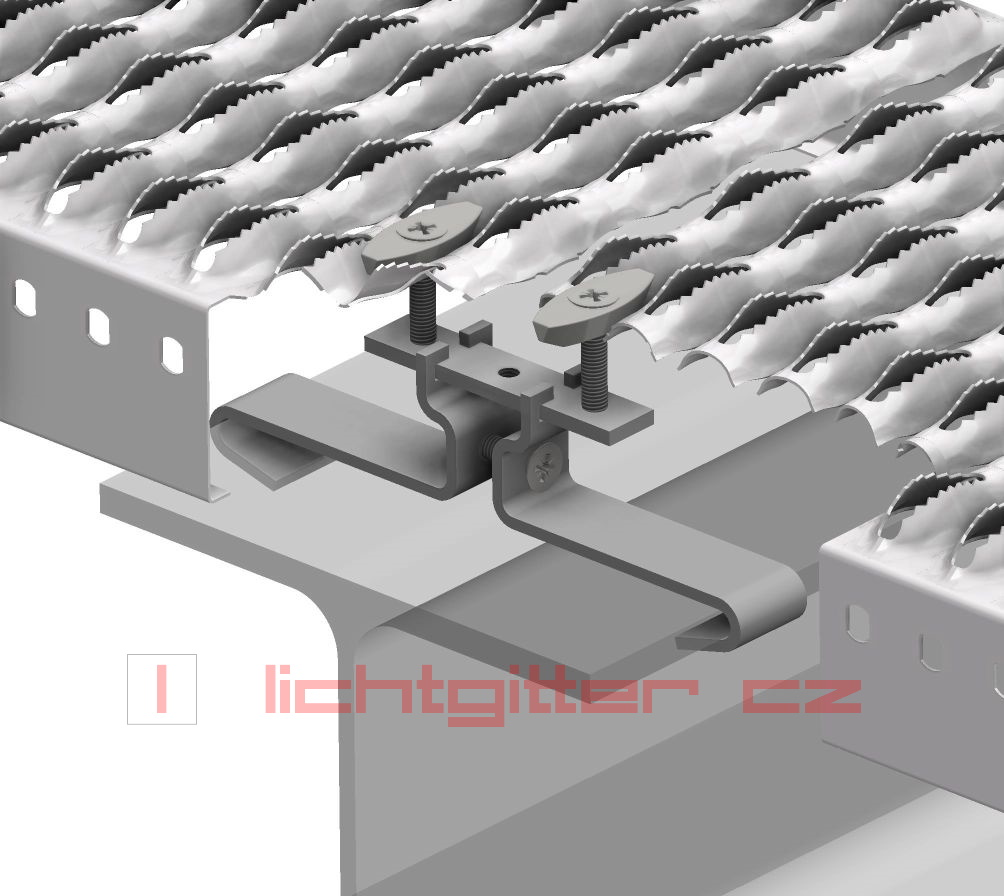

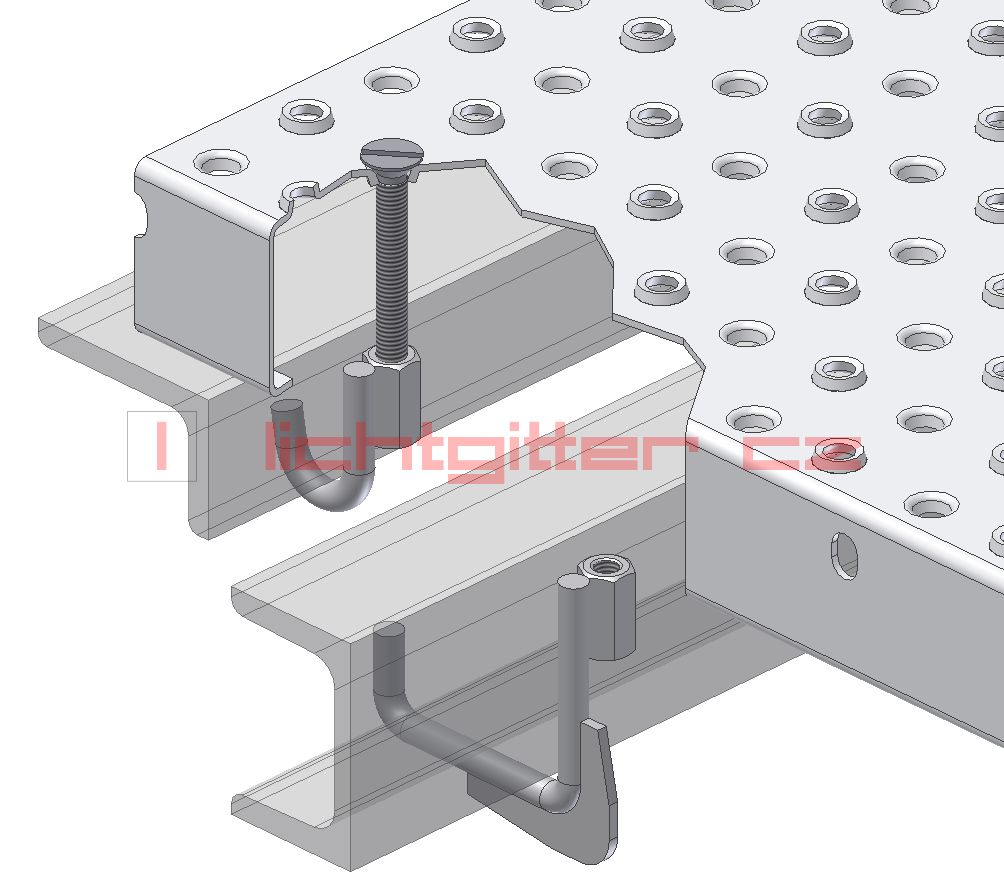

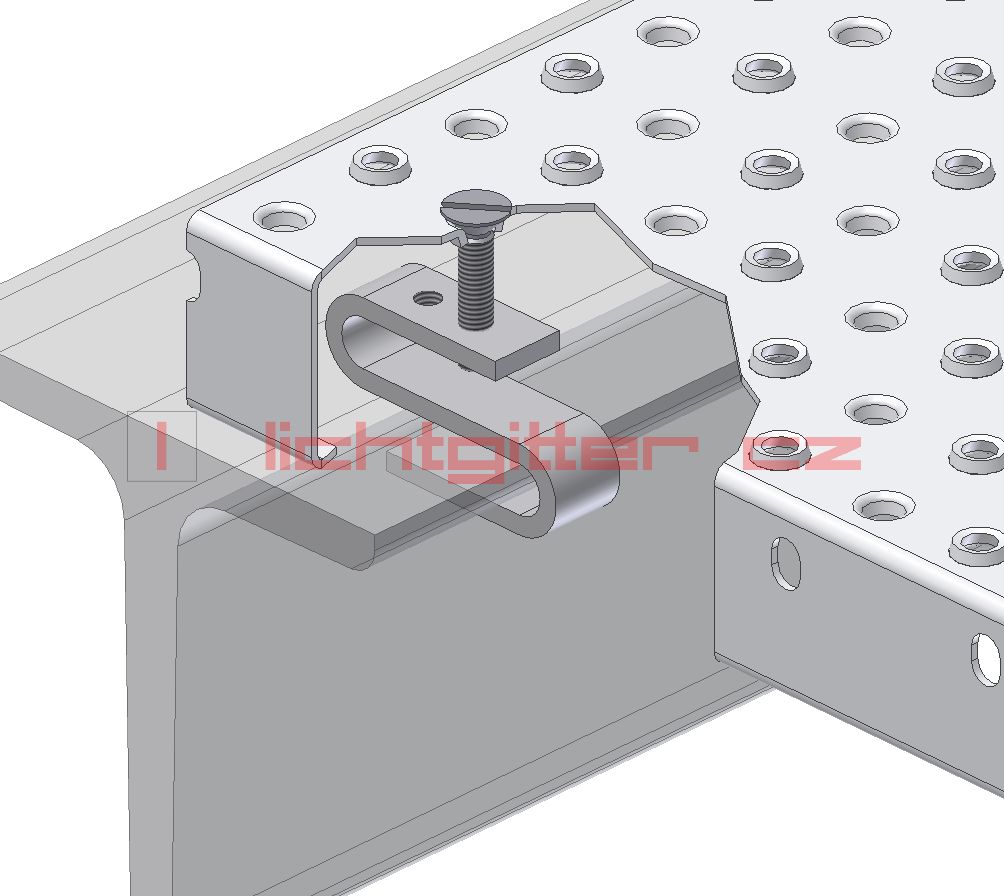

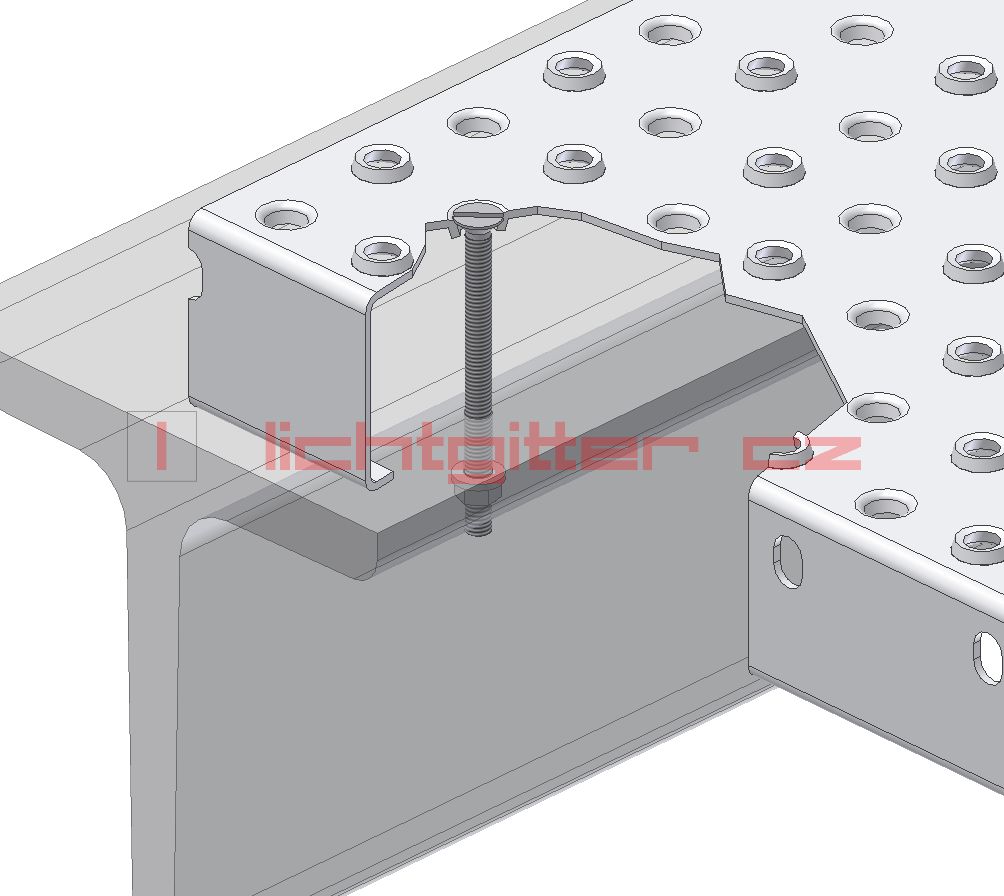

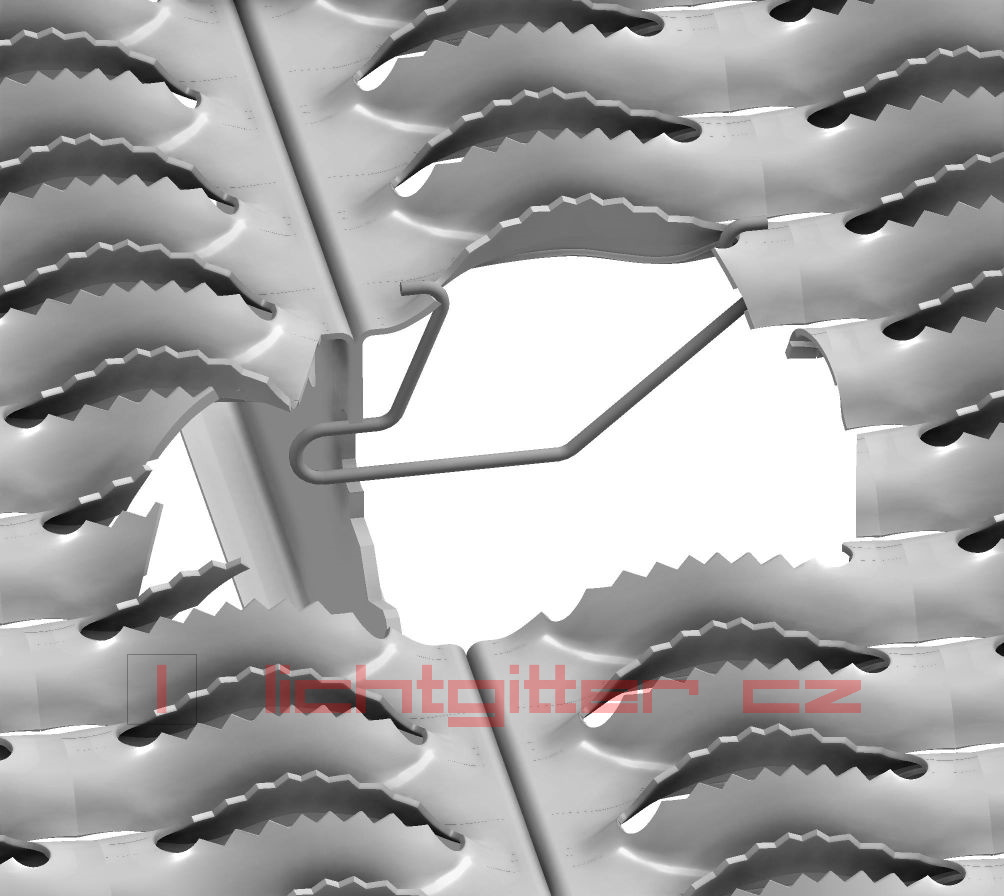

No. 25 S-Clamp

is a clamp connection consisting of:

- S-hook (suitable for underside support with a flange thickness of max. 9 mm)

- countersunk screw M8 x ... ISO 2009 (DIN 965)

- and for BZ-gratings additionally with „olive“.

This fixing is suitable for the types BR, BP, BP-Ü and BZ.

No. 26 Direct screw connection

makes a secure connection to the substructure, consisting of:

- countersunk M8 x ... ISO 2009 (DIN 965)

- washer 9 DIN 126

- nut M8 ISO 7042 (DIN 980), self-locking

With olive for BZ gratings

Fastening material suitable for BR, BP, BP-Ü, BZ and BN-O.

No. 27 Element butt joint

prevents the formation of trip hazards and increases load distribution on unscrewed elements with large span widths

Consisting of:

- connection part

- thread-cutting screw M5 x 20 DIN 7516 D

Fastening material suitable for BR, BP, BP-Ü, BZ, BN-O and BN-G.

No. 27 Connection clamp - new

prevents differing deflection of loaded and unloaded gratings so that a trip hazard > 4 mm cannot be formed.

Consisting of:

- spring steel clamp

Fastening material suitable for BZ.

No. 29 Screw connection

Consisting of:

- screw M8 x 20 ISO 4017 (DIN 933)

- washer 9 DIN 126

- nut M8 ISO 7042 (DIN 980), self-locking

Fastening material suitable for BR, BP, BP-Ü, BZ, BN-O and BN-G.

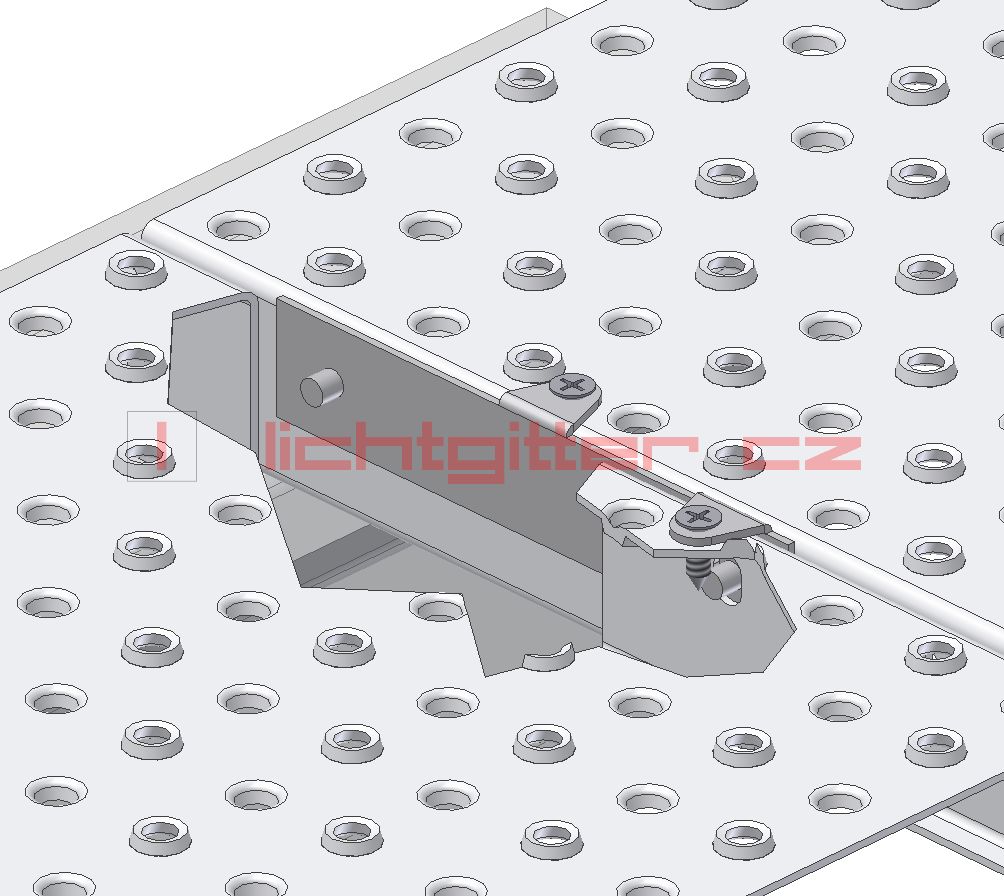

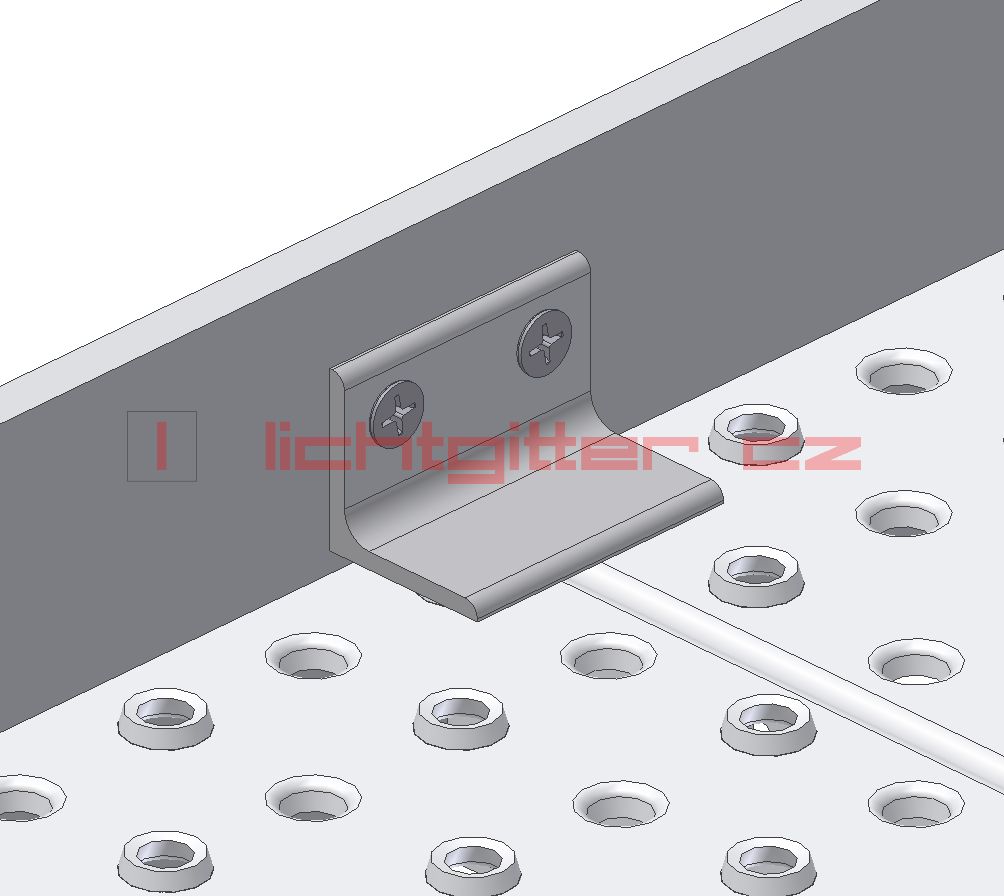

No. 30 Angle fastening

prevents lifting of perforated metal planks

Consisting of:

- angle piece 30/30/3....50 mm long

- 2 thread-cutting screws M5 x 20 DIN 7516 D

Fastening material suitable for BR, BP, BP-Ü, BZ, BN-O and BN-G.

No. 31 Butt strap

Suitable for connecting the grating elements together on the joint and for limited load transfer

Fastening material suitable for BR, BP, BP-Ü, BZ, BN-O and BN-G.

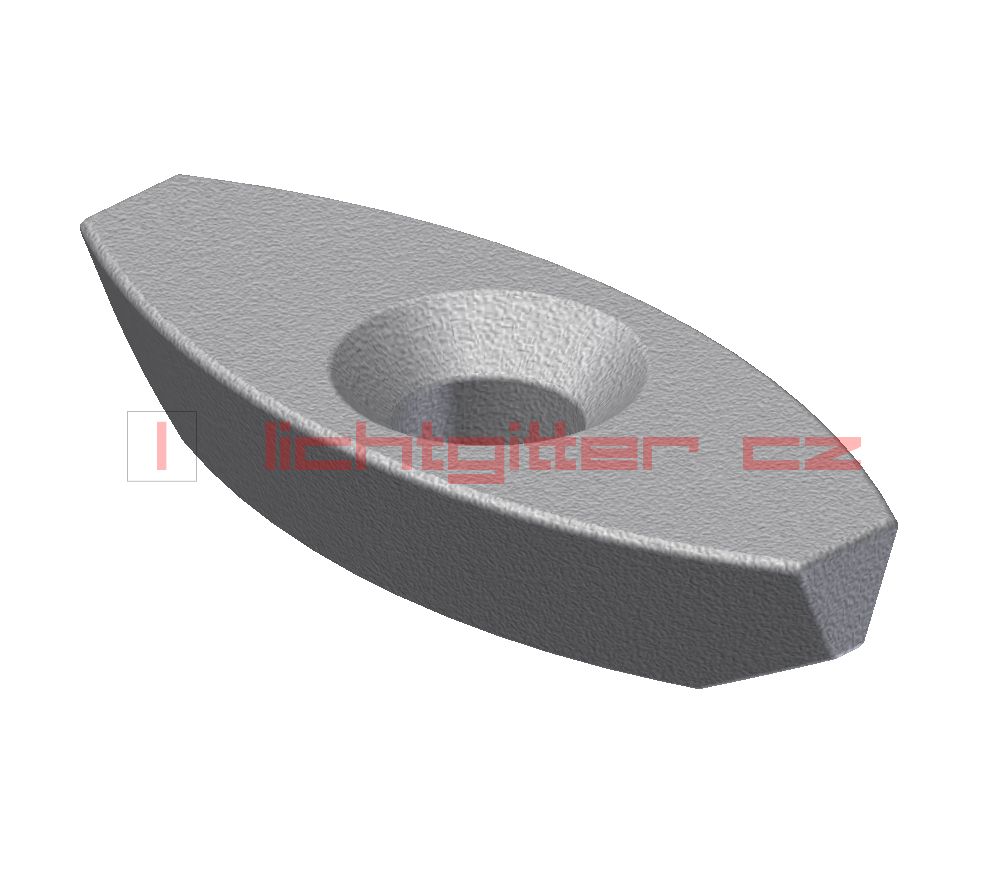

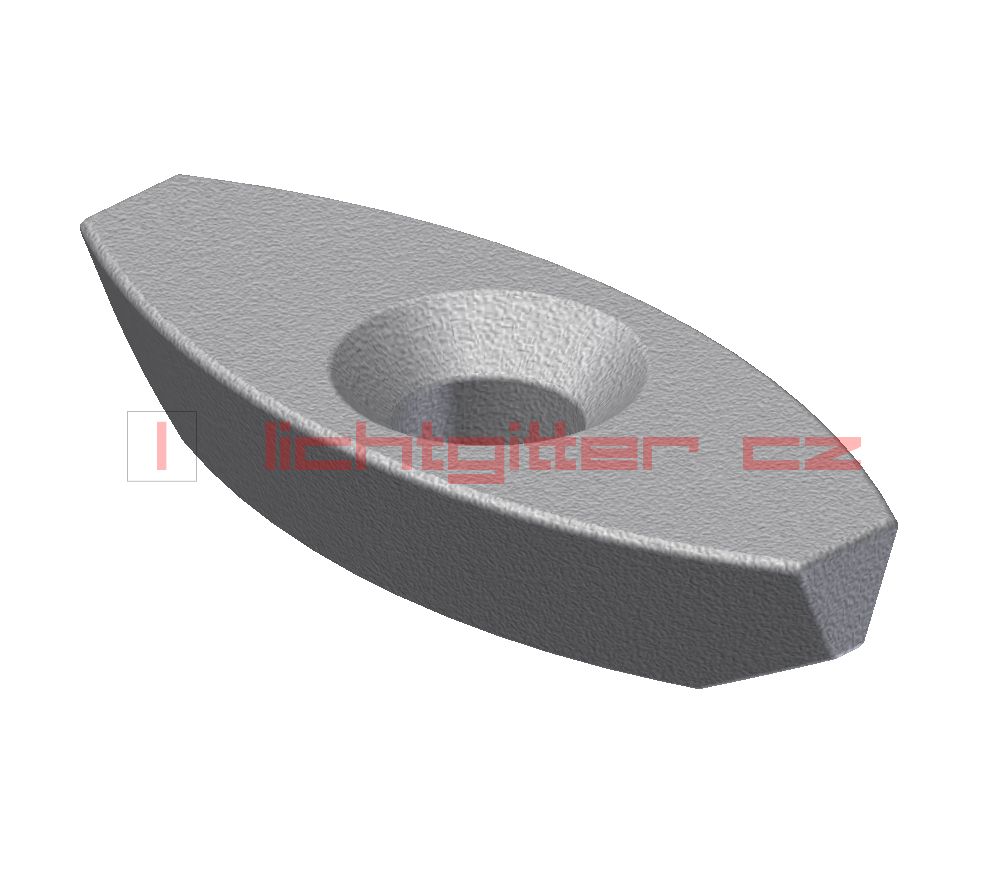

No. 32 Olive

Top of fastening for BZ perforated metal planks.

Made of grey cast iron without surface treatment and of PA 6.6 plastic.

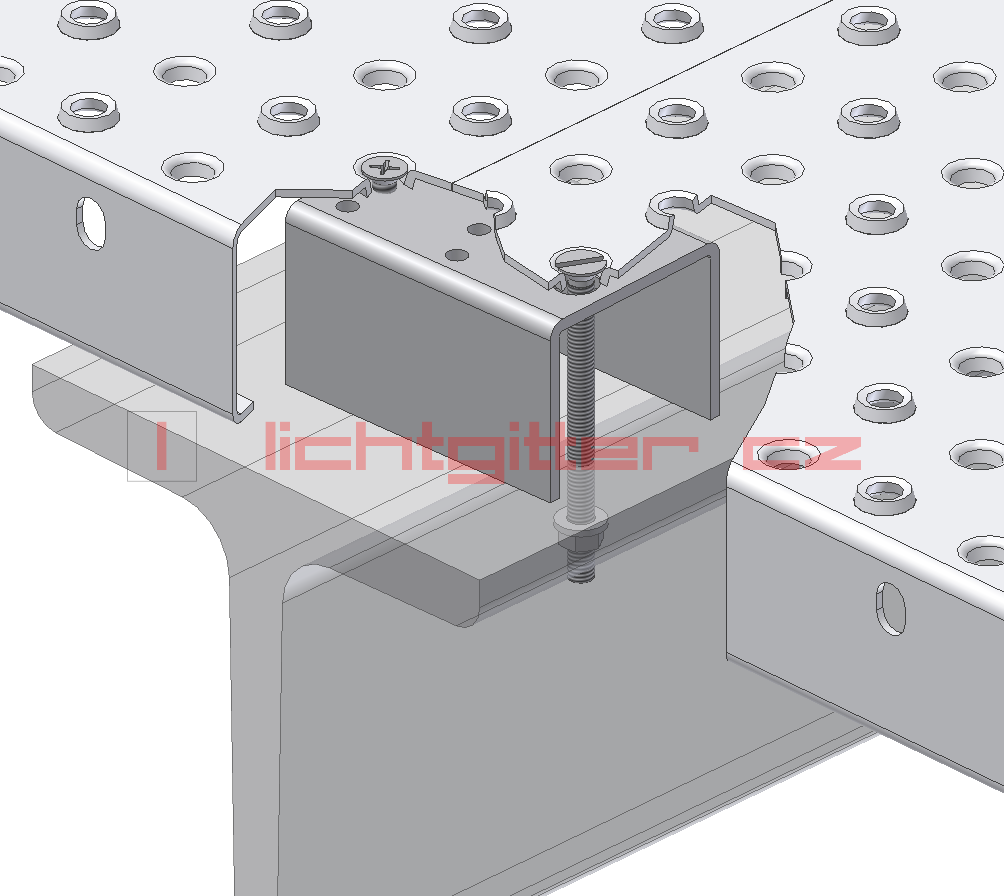

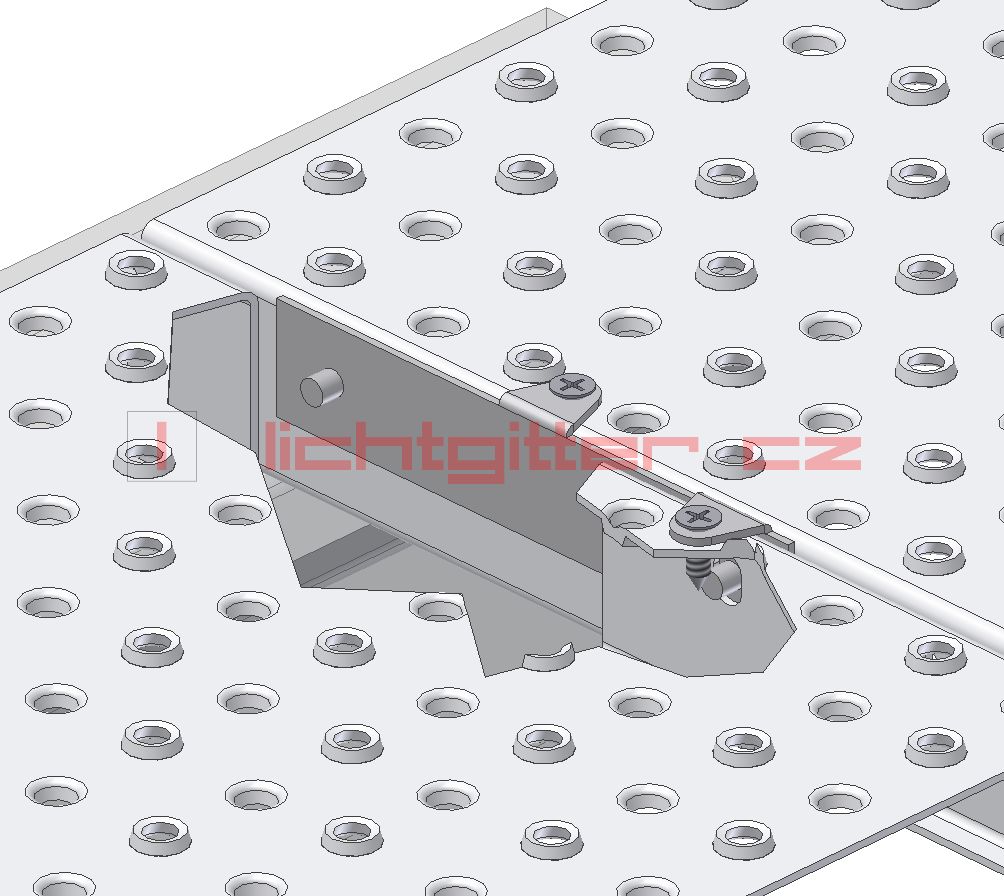

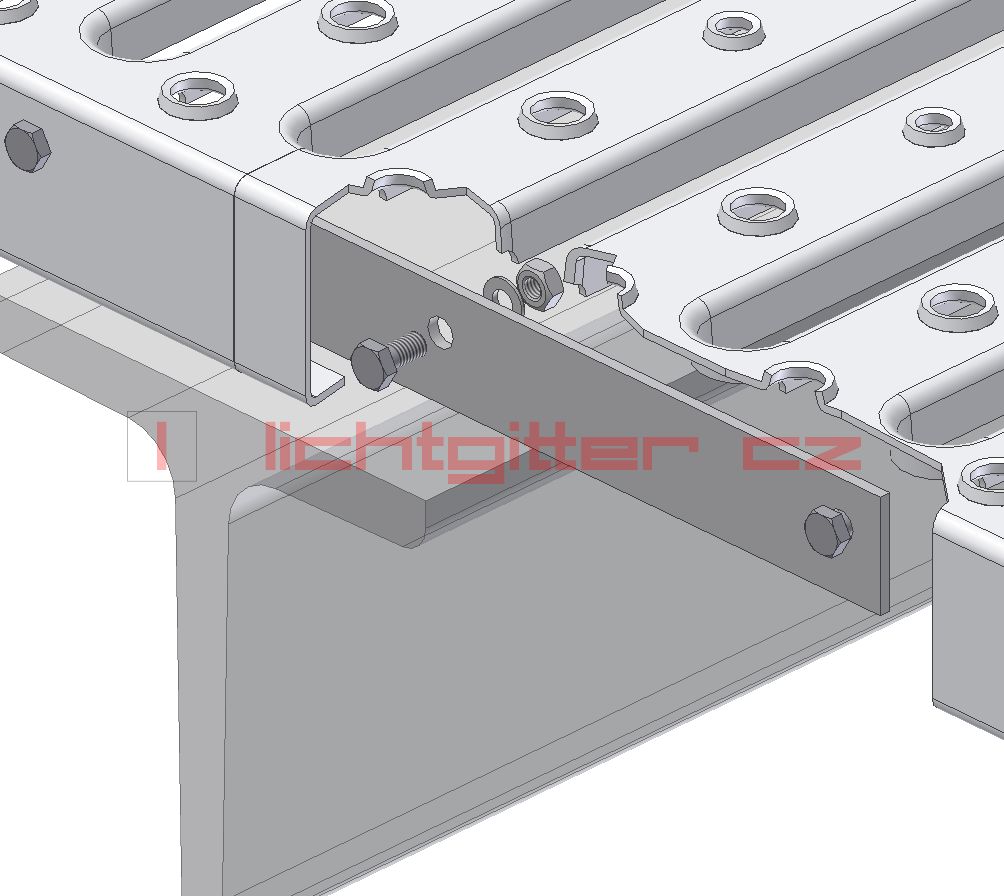

No. 34 Clamping claw

is used to fasten perforated metal planks to the substructure. The grating is pressed onto the steel structure with a defined clamping force by means of screw M12, to a suitable tightening torque. As a result a defined horizontal force is simultaneously transferred, thereby protecting the gratings against lifting.

Consisting of:

- Curved flat 50 x 8 mm

- Screw M12 x .... ISO 4017 (DIN 933)

- Washer 13 DIN 126 and nut M 12 ISO 7042 (DIN 980), self-locking

Alternatively with steel structure screw according to DIN 7990

Fastening material suitable for BR, BP, BP-Ü, BZ, BN-G and BN-O.

Homepage /

Homepage /

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.

Forge-welded gratings, pressure-locked gratings, stair treads, perforated metal planks, spiral staircases, GRP gratings and ladder rungs. Various material variants (steel, stainless steel, aluminium) with various surface finishes.  +420 596 496 511

+420 596 496 511 obchod@lichtgitter.cz

obchod@lichtgitter.cz